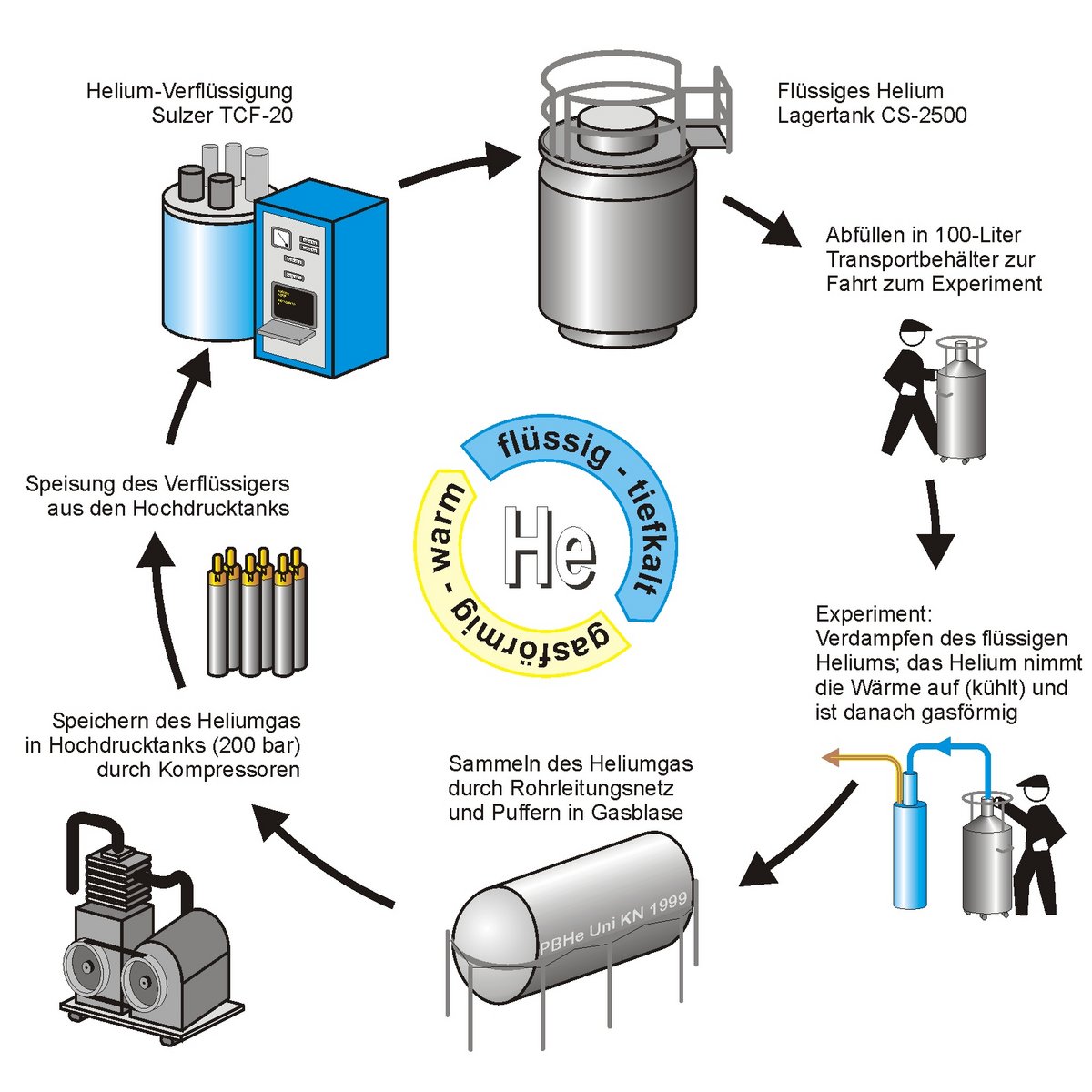

A supply of liquid helium for scientific experiments at low and lowest temperatures (4 K = − 269 °C) has been available at the University of Konstanz since 1976. Fundamentally, the whole helium system is divided into two interlinking sections:

- Helium liquefaction system with cryogenic storage for the production and storage of liquid helium;

- Helium recovery system for the collection and storage (= recovery) of gaseous helium.

The system is constructed as a cycle in which the scientific experiment (user) links the production (liquefaction) of cryogenic liquid helium with the recovery (collection) of warm gaseous helium.

The cryogenic helium absorbs the heat of the experiment and passes into the gaseous state; the gas is then collected and fed back to the liquefaction system to close the loop. During normal operation, each litre of helium runs 20 times in this cycle before it is lost due to leakage in the system.

Helium Liquefaction System

Central part of helium liquefaction is the turbine expansion machine TCF-20 by Sulzer. Driven by a 85 kW screw compressor by Kaeser, the machine reaches a level rise of 20 L/h liquid helium which is stored in a 2500 liter storage tank. 25 transport containers (AL RH-100) can be filled here in order to supply more than 40 cryogenic apparatus with liquid helium.

Helium Recovery System

The released warm (and thus gaseous) helium from the cryogenic apparatus is fed to the low pressure buffer (gas balloon with 25000 liter volume) via a pipeline system without any pressure. From here the helium gas is sucked by high pressure compressors (2x Bauer G22 having each 48 Nm³/H, 1x Sulzer-Burckhardt having 120 Nm³/h), compressed, dried and then stored in a high pressure vessel (4 x 1000 L @ 200 bar, 1 x 2800 L @ 200 bar). The helium is then re-fed to the liquefaction system.