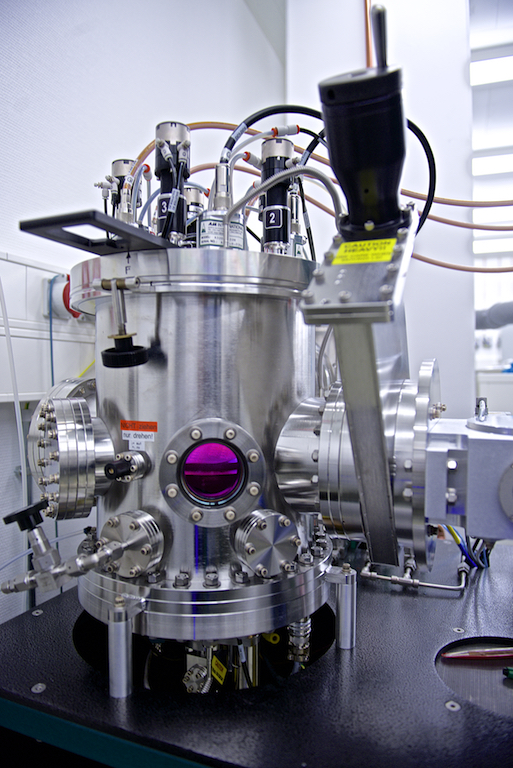

We employ two sputtering systems manufactured by AJA International, Inc. Both systems achieve a base pressure of about 10-8 mTorr in the ultra high vacuum regime. Therefor, clean and controlled sputtering even of heavily oxidizing materials is possible. Each machine is equipped with a load lock to facilitate a quick exchange of samples without venting the respective entire main chamber.

The ATC Orion 5 UHV is a very versatile system with many different target materials in stock and the possibility of co-sputtering. Aquiring new target materials is comparatively inexpensive due to the small target size of 2".

The key features are:

- target size: 2"

- 3 RF and 2 DC guns

- process gases: Ar, N2 and O2

- heater up to 850 °C

- co-sputtering

- uniformity better than 2.5% over 4" diameter samples

The ATC-2200 is a large machine used only in solar cell processing and hence is restricted in the available target materials to prevent contamination. However, the target size of 4" guaranties a uniformity better 2% on large 6" substrates.

The key features are:

- target size: 4"

- 4 RF guns and 1 pulsed DC

- process gases: Ar, N2 and O2

- heater up to 450 °C

- uniformity better than 2% over 6” diameter wafers

Reference: AJA International, ATC & ATC Orion Series Sputtering Systems - Installation & Operation Manual, 2005.